Simple Asset Management for SMBs

No more lost assets, skipped maintenance or missing inventory.

The best asset management software for modern business.

No email required

Asset tracking should be simple.

I want to know who has what equipment, when they got it, and when it's coming back. What is broken or lost, and what do I need to buy? If you give Assetbots a try, I think you'll be amazed that you ever lived without it.

Easy to use

equipment checkout

Our mission is to make software that is not only easy, but joyful to use. We know you've heard it before, so we expect you to be skeptical.

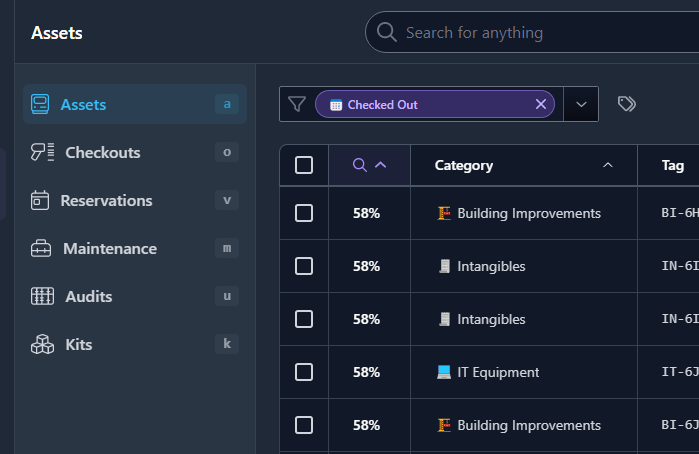

Search for anything, anywhere

Save search filters you use frequently

Keyboard shortcuts for common actions

You won't believe

how fast it is

Every action you take is registered and responded to immediately. Stop waiting for the machine and start getting things done.

Find anything instantly

Save your changes instantly

Built-in

barcode and QR code scanner

More than scan-to-search, our scanner is deeply integrated and works on any device. Rapid-fire scan to check-in, checkout, add new assets or find existing ones.

Scan from any device with a camera

Fast, reliable scanning of any barcode or QR code

No special hardware to buy

Nothing to install

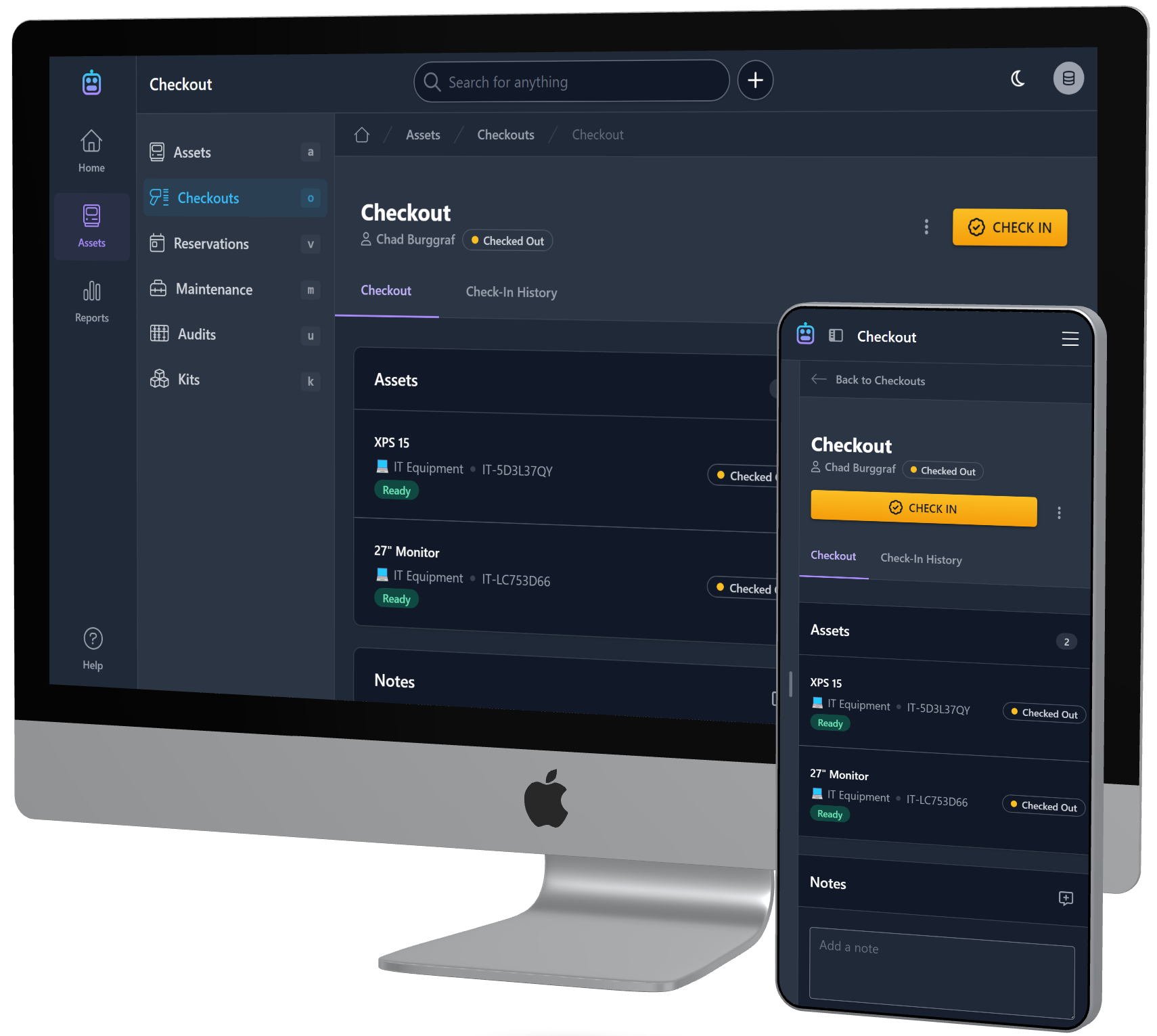

every feature on every device

An asset tracking app that works on any device, no download or installation required. You'll never have to wait for updates to the iPhone or Android version again.

Work on the go from your phone

Or on the couch from your tablet

Or at the office from your laptop

Built for every industry

Every organization has assets. Assetbots will save you time and money managing them effectively.

Education

Schools track IT equipment and office supplies to manage costs and increase accountability.

Healthcare

Healthcare organizations track medical equipment and supplies to understand inventory and save time.

Construction

Construction companies track tools and safety equipment to reduce loss and prevent theft.

Government

Government agencies track vehicles and office equipment to improve budgeting and simplify audits.

Hospitality

Hospitality companies track furniture and linens to streamline purchasing and improve forecasts.

Technology, Retail, Non-Profit and more

Every organization can track assets and inventory to understand spending and reduce waste.

Hello, features

Everything you need to build a world-class asset management program is included, plus a little extra.

Custom Fields

Track exactly the data you need with custom fields. Includes standard fields like Text and Multiple Option, and advanced fields like Autocomplete, Money and Address.

Check-In and Checkout

Maintain auditable chain-of-custody records and keep people accountable. Know at-a-glance who has every asset, when they received it, and when it is being returned.

Reservations

Make sure equipment is available for the right person at the right time. Calendars visualize when assets are needed, when they are returning, and when they are being repaired.

Barcodes and QR Codes

Scan barcodes or QR codes to find, assign or return assets from any device with a camera. Scan asset tags, serial numbers, UPC codes or any other code in any data field.

Repairs and Maintenance

Track maintenance, repairs, and warranties. Prevent broken assets from being checked out and attach work orders and invoices to keep everything in one place.

Kiosks

Create self-serve kiosks for customers, clients, or employees. Scan NFC labels, employee badges and barcodes to checkout tools and equipment in seconds.

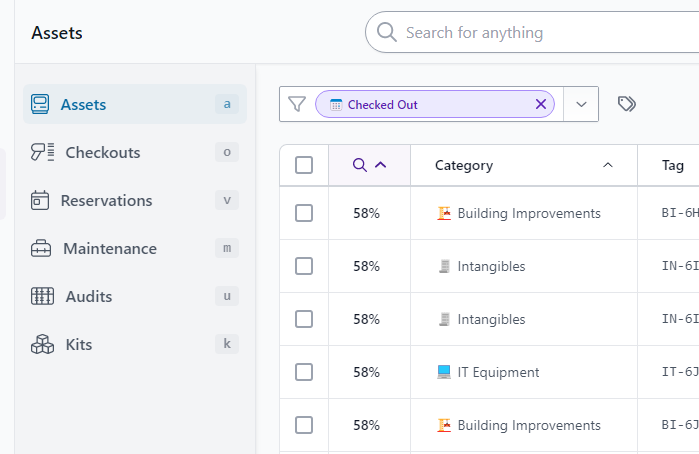

Search and Filter

Find exactly what you're looking for with fuzzy and boolean search. Save complex searches and custom table layouts to view your data exactly the way you want.

Reports

Explore and visualize your data with activity reports, depreciation reports, warranty reports and more. Export to Excel or CSV for even more flexible reporting.

Integrations

Integrate with other software used by your organization. Increase accuracy and reduce data entry by syncing with Active Directory, Google Workspace and more.

Role-Based Access

Invite your team to collaborate without worrying about data integrity. Grant users a range of access levels, from read-only up to full administrative control.

Import Data

Sophisticated import tools allow you to get started quickly. Import assets, people, categories, labels, locations and event checkouts from a single Excel or CSV file.

Print Asset Tags

Design and print asset tags for existing or new assets. Customize branding and contact information with real-time preview for up to 1,000 assets at a time.

Mobile

Manage your assets anywhere at any time without installing any software. Our mobile web application is always up to date and never missing features.

Work Offline

Scan assets in a sub-basement with no Wi-Fi. Create reports on the train. Work from anywhere and your changes are synced automatically when you're back online.

Real Time

Never refresh the page or reload the screen again. Your whole team can work without fear of conflicts as changes are synchronized instantly.

Multi-Tenant

Create a database for each client or department you work with. No need to sign-in to multiple accounts, Assetbots is multi-tenant by default.

Not ready yet?

Let's keep in touch! We will never share your information. Opt-out any time.